THELEN-machines was founded in 1993 as a design office for machine and special constructions and has continued to develop over the years. In the meantime, we primarily advise on the acquisition of new machines and industrial plants, design them and work closely with market-leading machine suppliers. Today we are the representative of well-known international machine manufacturers and at the same time offer our customers a local after-sales service.

The following machines from our affiliated companies complement the program:

- Feed bunker

- Infeed water soaking basin

- Elevators and height conveyors

- Conveyor belts

- Conveyor screws / Transport auger

- Steam peeling plants

- Rod drum washing machines

- Brush washing machines (drum)

- Brushes Washing Machines (Vertical Brushes)

- Cubes-, Strips-, Slices-Cutting Machines

- Post-wash basin

- Dewatering vibrating channels

The steam peelers can be found in leading potato and vegetable processing plants around the world. We offer a wide range of processing solutions to suit your needs. Today, companies are investing in potato peeling machines that can deliver significant savings in raw material, maintenance, and energy costs.

Optical sorting machines and steam peeling lines

Sensor-based sorting equipment and food processing technology for fresh and processed food suppliers.

Applications:

- Potato + vegetables whole + sliced

- All kinds of lettuce

- Spinach, kale, cabbage

- Pickles - Snack Food

- Nuts

The development of state-of-the-art sorting technologies, the optimization of your production process and the guarantee of consistently high food quality are our strengths. The modern sorting systems check millions of individual product parts per hour and, thanks to higher yields and better application, usually achieve product recovery or savings of 5 to 10 percent.

With a per capita consumption of 60 kg of potatoes per year at 80 million in Germany, 5% savings correspond to 240 million kg or 240,000 tons of potatoes.

Machines for container handling supplement the program:

- Empty glass and empty can depalletizing systems

- Cleaning systems (blow out - wash out)

- Glass / can turning stations

- Tunnel washing machines

- Blow-out tunnel - drying tunnel

- Ink Jet Coding (labeling)

- Cage loaders and cage unloaders for sterilization processes

- Palletizing, e.g. still without a label on block packs for interim storage

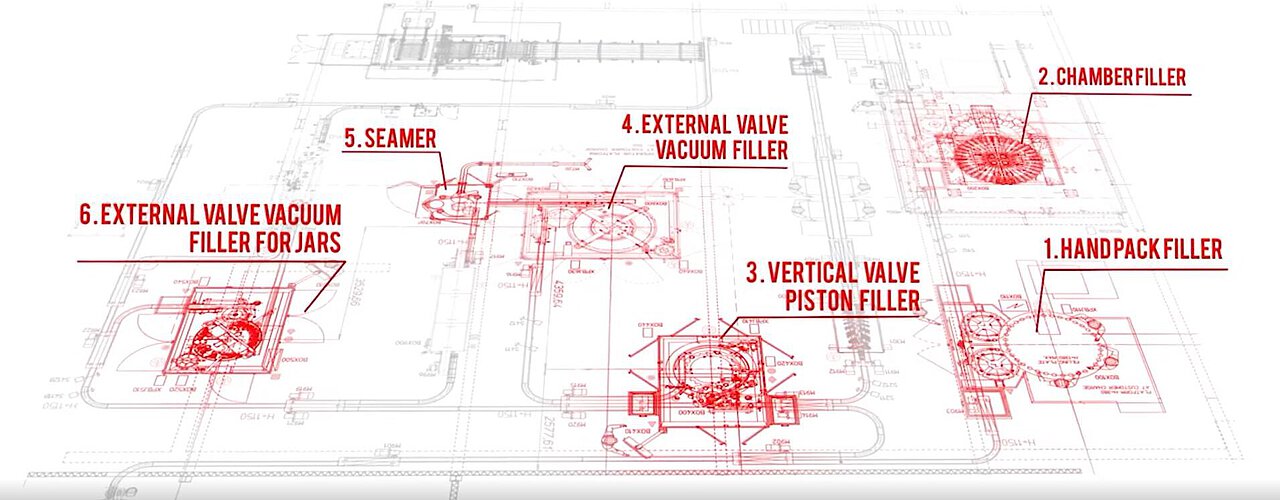

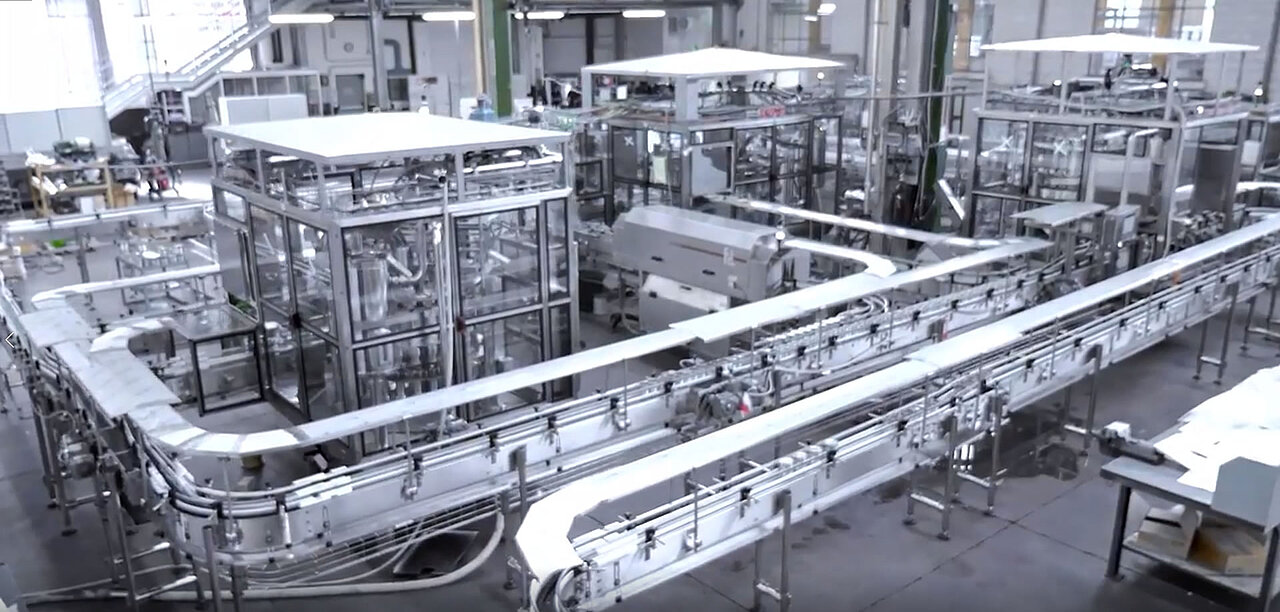

Machines for food processing and bottling

The machines are in the middle to upper performance range and are known for their very stable construction and design as well as above-average reliability.

To mention in particular:

- Telescopic filling machines

- Telescopic filling machines pet food

- Vacuum filling machines

- Vacuum filling machines pet food

- Piston filler

- Row filler

- Twist-off capping machines

- Can seaming machines

Areas we handle:

- 100 - 400 jars/cans/mini - preserves

- 300 - 1000 cans / mini drinks

The machines are in use in most of the leading food processing manufacturers in the industry and they enjoy an excellent reputation.

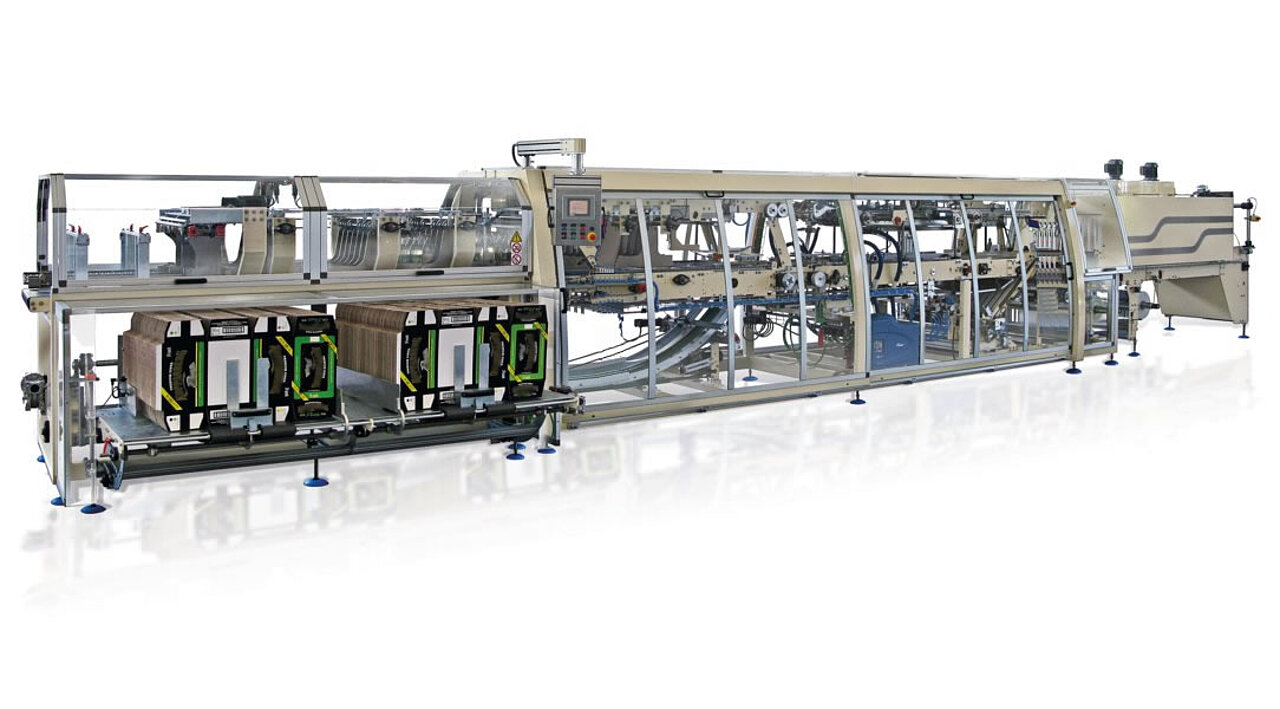

"End of the line" is also part of the portfolio.

But also pack special solutions such as foil bags in previously erected boxes etc.:

- Tray packer

- case packer

- Palletizer

- Tray and pallet wrappers

- Pallet wrapper

- Pallet transport (roller conveyor/chain conveyor)

- Pallet transport (autonomous driverless vehicles)

Specialized cooperation partners

A number of highly specialized cooperation partners round off the profile and enable us to implement special systems/constructions and very complex projects.

- Conventional or robotic automation technology (Packer / Pic & Place)

- Special machine builders for applications that cannot be bought “standardized”.

- Assembly teams with welding permits, e.g. stainless steel steam pressure lines

- Stage builders for stairs - platforms - subframes, for machines and entire lines

- Engineering office for the final on-site CE conformity declaration including risk analysis according to the machine directive of a complete installation / line.

Expert office for machines and systems.

Publicly appointed and sworn in, in Germany and also certified Europe-wide by the European personnel certification body "EuroKompZert" according to the ISO/IEC 17024:2012 standard international experts for the evaluation of machines, systems and equipment.

Your contact in the event of average or machine damage for court-usable evidence preservation reports.

learn more

Turnkey solutions out of one hand

Thelen is your first point of contact when it comes to the topic of food processing machines. Benefit from our more than 30 years of experience. From advice/planning and construction, through production to on-site assembly and commissioning. We are your reliable partner and thus ensure your long-term success.

Our specialty is optical sorting systems, process, filling, and packaging technologies for the food processing industry. In this way, we can plan and deliver complete lines from the product feed through to the final packaging.

We represent market leaders in your field, will advise you on inquiries for new machines and process all spare parts and service orders for you.

In addition to good advice and delivery of the machines, we of course also offer good service - because that is also part of our philosophy. This also includes service technicians. Because their use is particularly important to avoid unnecessary machine downtimes in the event of faults. We offer service for the machines supplied by us and our partners, but in emergencies we also repair third-party machines that the customer already has.

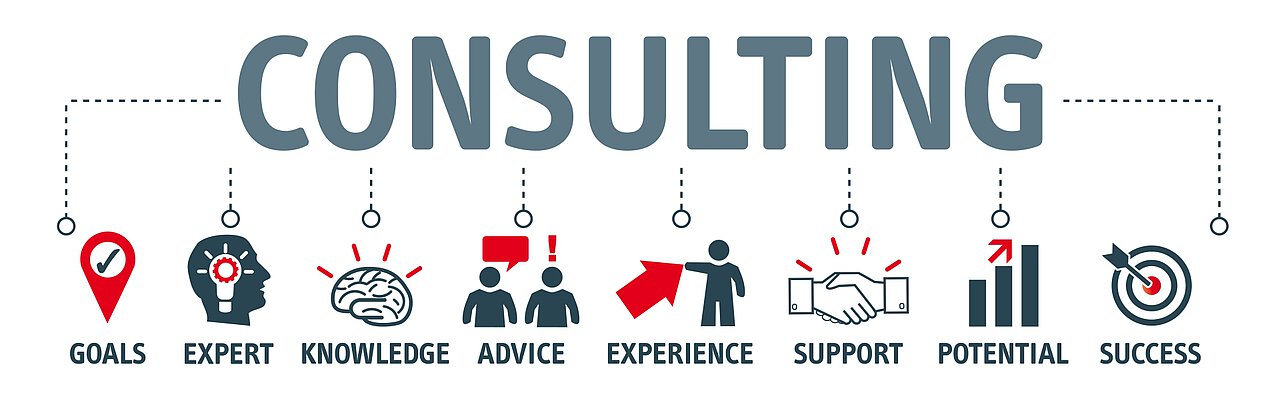

Advice is very important to us.

We take our self the time to discuss your task with you on site from A-Z.

Based on the findings, we determine the most suitable, optimal machine for you and the corresponding configuration in terms of performance, equipment, format sets, etc.

Only those who know all the facts can decide on the right technology.

We are also your contact for planning.

We support you in planning the trade and the peripherals and additional devices or machines that may be required.

We measure at your site, create a drawing of the local conditions, and plan your new system / machine so that you can see from a drawing how the final installation will take place later in your company.

During the implementation of the project, we remain your contact for delivery, unloading, installation, assembly and commissioning.

We are available to coordinate with other suppliers, such as interface coordination, etc., and can take over the coordination of the individual trades if required.

Coordination of the installation, assembly and commissioning can be coordinated and planned by us.

This in direct cooperation with your own staff, so that all activities conform to the internal planning / production.

If a final CE declaration of conformity is required for an overall installation, we and our partners are able to create one for you. Such an overall declaration of conformity is required as soon as machines or systems from one or more manufacturers are linked in a line.

After commissioning, there are often questions that we are available to answer.

Our service does not end after commissioning.

We help you to plan your preventive maintenance by making suggestions and developing concepts for inspection intervals.

We make recommendations for consumables and spare parts that should be kept in stock.

If a spare part or service is required, we are there for you and can be reached. This also outside of normal office hours.